Get to know the newest roof in town: Hybrid roof assemblies

AIA partner GAF explores hybrid roofs, which combine various roof materials to help meet efficiency, durability, resiliency, and sustainability goals.

Hybrid roofs represent an innovative approach to roofing, blending various roof materials to help meet energy efficiency, durability, resiliency, and sustainability goals. Unlike traditional roofing systems that typically utilize a single material chemistry—such as modified bitumen or TPO—hybrid roofs combine these products to leverage the strengths of each.

What is a hybrid roof?

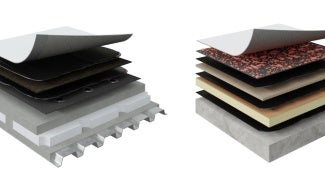

A hybrid roof assembly is where two roofing membranes, composed of different materials and product technologies, are combined in one single roof system. One type of hybrid assembly consists of a modified bitumen base layer with a cap layer of a thermoplastic single-ply membrane, such as thermoplastic polyolefin (TPO) or polyvinyl chloride (PVC) or PVC-KEE. Each component of the roof system is intentionally selected for its strengths, and together, the system combines the best of all the technologies present.

Asphaltic or modified bitumen membranes, when used as the first layer of a hybrid assembly, provide the redundancy and protection against puncture that has made it a successful roof for decades. However, modified bitumen assemblies must have a cap sheet consisting of a granular surface to provide UV protection, and they have minimal resistance to ponding water and certain chemical contaminants.

The combination of an asphaltic base sheet with a single-ply membrane as a cap sheet increases the overall system thickness and robustness compared to a traditional single-ply system. Additionally, the single-ply membrane can help address some of the shortcomings of a modified bitumen assembly on its own. PVC and KEE membranes may also provide protection where exposure to chemicals is a concern, and they generally hold up well in ponding water conditions. TPO membranes may allow for storm water capture when the membrane is certified per NSF P151.

A higher Solar Reflective Index (SRI) value can be achieved using a single-ply membrane with both high new and aged SRI values than can sometimes be found with modified bitumen cap sheets. When higher SRI value options are chosen, the single-ply membranes placed as a cap layer over bitumen systems can decrease the roof surface temperatures and potentially help reduce the heat island effect of the building.

One caveat when designing and installing a hybrid roof assembly is that there must be a separator between the two materials. This is due to the chemical incompatibility of the single-ply membrane and the modified bitumen. The most common option for new construction is the use of a fleece-backed membrane where the factory-applied fleece backing acts as the separator.

What types of projects can benefit from a hybrid roof assembly?

Hybrid roof assemblies can be a logical choice for data centers, education facilities, and hospitals due to their strong protection against leaks and multi-ply system redundancy. The redundancy of the second layer of membrane in the form of an asphaltic base sheet provides a secondary protection against leaks if the single-ply membrane is breached.

Hybrid roof systems are not confined to new construction. A key benefit of a hybrid roof assembly occurs in retrofit or recover scenarios where there is an existing-modified bitumen or built-up roof (BUR) that is in overall fair condition and with minimal underlying moisture present. A single-ply membrane can be installed on top of the existing roof system without an expensive and disruptive tear-off of the existing assembly. The addition of the single-ply membrane adds reflectivity to the existing darker colored membrane and increases the service life of the roof assembly due to the additional layer of UV and weather protection. Additionally, the single-ply membrane can be installed with low-VOC options that have minimum odor and noise disturbance if construction takes place while the building is occupied. This can include mechanical attachment, induction welding, or adhesives.

Hybrid roof assemblies are here to stay

The intentional combination of materials in a hybrid roof assembly aims to combine the puncture resistance and durability of modified bitumen with the UV protection, resistance to ponding water, ease of repair, and resistance to certain chemicals that are benefits of single-ply membranes. The combined attributes of bitumen systems and single-ply membranes complement each other, providing a durable, efficient, and redundant roof system.

You can build your own roof assembly and corresponding specification using our BuildYourRoof tool. Also, feel free to reach out to our Building & Roofing Science team with questions and project support.

AIA does not sponsor or endorse any enterprise, whether public or private, operated for profit. Further, no AIA officer, director, committee member, or employee, or any of its component organizations in his or her official capacity, is permitted to approve, sponsor, endorse, or do anything that may be deemed or construed to be an approval, sponsorship, or endorsement of any material of construction or any method or manner of handling, using, distributing, or dealing in any material or product.